Rolf glasses

Explore the world of Rolf glasses, crafted from natural materials.

Sustainable eyewear handcrafted in Austria.

This is merely a taste—a hint. To truly discover Rolf, you’ll have to go beyond the digital world. Rolf starts where the Internet ends.

Head to your local Rolf partner—where the real experience begins.

Rolf glasses near you.

ROLF. FROM NATURE

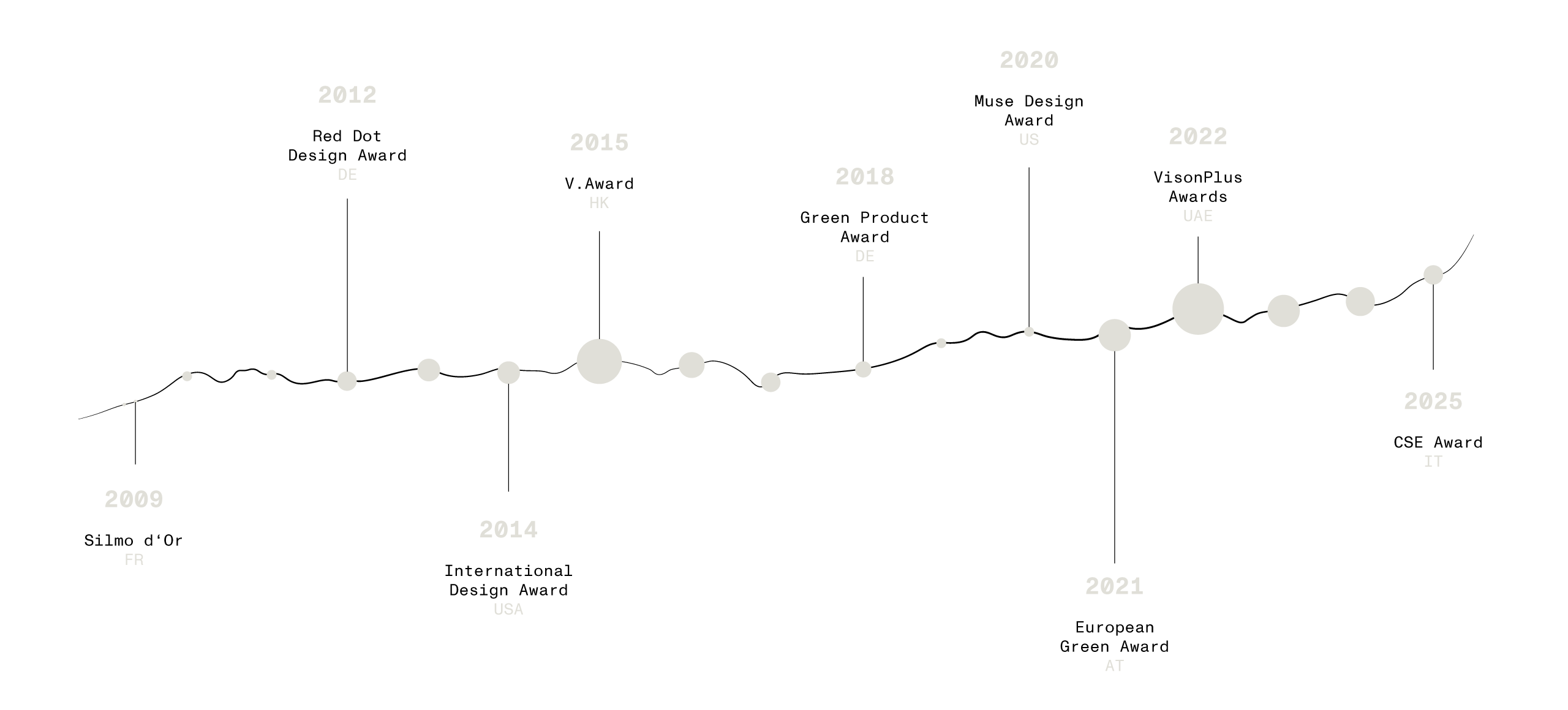

“The jury singled out the “Bean Glasses” as an excellent sustainable product design that not only offers ecological advantages but also functional benefits for the user. Another outstanding feature is that the production process has a minimal ecological footprint thanks to 3D printing. The jury also recognized Rolf’s entrepreneurial mindset and holistic, sustainable approach as a pioneering approach for manufacturers who are making a name for themselves in a mass market with sustainable quality and innovation. All in all, Rolf is taking a path with its eyewear that extends far beyond the horizon of eco hypes.”

–European Green Award

Rolf values

Plant-Based materials.

Planet Earth.

An essential part of our philosophy is to leave a better planet than the one we found.

Rethink. Reuse. Reduce.

ROLF values

Plant-Based materials.

Rolf stands for quality and innovation beyond the eco-hype. We produce high-quality eyewear from plant materials: wood, stone and bean.

Planet Earth.

An essential part of our philosophy

is to leave behind a better planet than the one we found.

Rethink. Reuse. Reduce.

Rethinking is in our DNA. Sometimes we even rethink the entire industry. Our goal is to reduce our impact on the planet.