Manufacture.

A glimpse into contemporary manufacturing

As you step into Rolf’s premises, you instantly feel the distinctive atmosphere: vibrant, relaxed, and driven by authentic passion. In this modern manufactory, numerous skilled hands carefully craft unique frames from natural materials—with precision, care, and an eye for the extraordinary.

How our wooden glasses take shape.

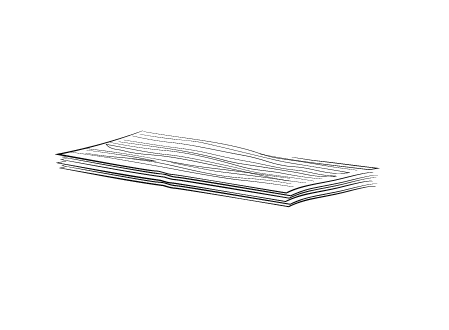

Exquisite veneers

It begins with selecting the finest wood veneers. Each piece undergoes careful inspection to ensure the ideal foundation for the frame.

High-precision milling

The wood is meticulously milled to form the shape of the glasses. After every stage, we carefully inspect the components to ensure a perfect fit before moving on to the next step.

Finest craftsmanship

Next is the delicate handcrafting: we sand, clean, and diligently inspect the glasses down to the smallest detail. Any minor imperfections are promptly corrected, and the design is carefully refined with precision.

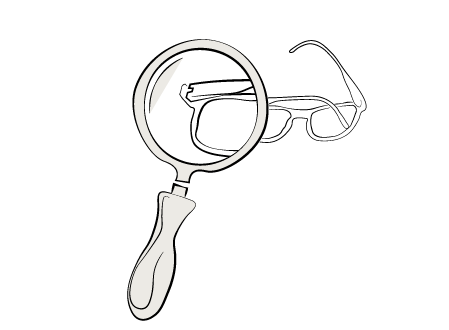

Tested quality

We ensure that the spectacle frame is perfect in every detail. Surfaces, joints, and shapes undergo a final inspection to ensure the utmost quality.

Final handles

Finally the glasses precisely assembled, and then thoroughly cleaned, inspected, and prepared for shipment.

Packed with love

The final step, each pair of glasses is carefully packaged to ensure that theyarrive safely and in perfect condition.

How our bean spectacles take shape.

Design & Construction

Our glasses are designed and developed right here in Weißenbach. With a unique design, we pay close attention to every detail to ensure each pair not only looks great but also fits perfectly and makes a bold statement.

The design is brought to life using a high-tech 3D printer and a truly unique material: castor bean powder. With cutting-edge printing technology, we craft the ideal shape for each pair of glasses—transforming a concept into a true work of craftsmanship.

Loops

The frame components are refined in a specialized grinding drum until the surface is just right. Every detail is carefully perfected to ensure the glasses are exceptionally comfortable to wear.

Glasses are created

One front piece, two temples, two rubber rings, and a clever design — the FlexLock joint embodies the beauty of simplicity. No screws, no wear-and-tear components, just maximum stability and long-lasting durability.

Insert glasses

Of course, the lenses are essential! They complement the frame and bring the glasses to life.. Following a final quality inspection, the glasses are ready to be dispatched.